CALIP Group has just taken a new step towards electric vehicle equipment manufacturers by integrating a new skill in MIG welding.

In order to meet the specifications of our client, manufacturer of very high-end electric vehicles, our profilé CALIP Normandie plant has integrated a new MIG welding unit. in the 3e part of its Moult building (14).

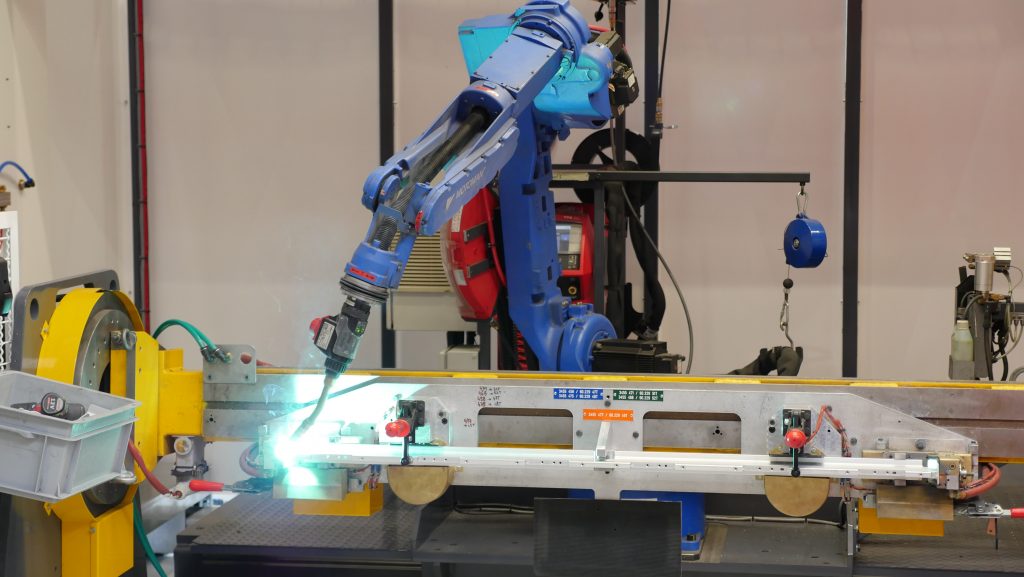

This automated MIG welding cell, installed by our partner supplier ACG, welds the elements that make up the battery pack of a new model of very high-end electric vehicle.

The components of the battery pack are machined on site from aluminum profiles. The welding robot then performs the welds of the sub-elements. The elements are then sent to the manufacturer for assembly.

This liquid welding process is very common in the automotive industry since it can be easily automated. Welding is obtained by adding metal, here aluminum, by creating an electric arc which liquefies the filler metal and the contact surfaces of the connected parts. The presence of oxygen and humidity being prohibited, a neutral gas is simultaneously diffused by the welding head.

Our R&D department took up the technical challenge of obtaining quality weld seams, despite the restrictive characteristics of aluminum. It is a very heat conductive material and has a low melting temperature (around 650 ° C), so special attention must be paid to regulating the quality of the solder bath, especially when there are different thicknesses to be welded. In addition, we ensure that our welds do not produce alumina (aluminum oxide) which could cause cracks during cooling, but also that there is no presence of humidity to avoid bubbles in the weld bead upon cooling.

Production has started and we plan to produce more than 10,000 per year.

“The battery pack for this top-of-the-range electric car model, which will be marketed from September 2021, will be entirely designed by our Moult plant. " Samuel Guérin - Director of CALIP Normande profiled